PRODUCTS

Standard Openings (0" - 48")

Oversized Openings (48"+)

Individual Components

MEET OUR TEAM

Engineering & Support

Customer Service & Sales

Interested in joining the

Legacy Team?

We're rapidly expanding our New York office.

Browse our representatives

by our directory or map.

Contact an expert in your area!

Product Information

Building on years of experience providing vital flood zone protection for doorways, Legacy now offers reliable, cost-effective flood barrier systems for virtually every building opening exposed to potential high-water flooding. Installing Legacy flood barriers can help satisfy National Flood Insurance Program (NFIP) requirements for coverage in designated flood zones, along with providing invaluable peace of mind to building owners hoping to minimize flood damages.

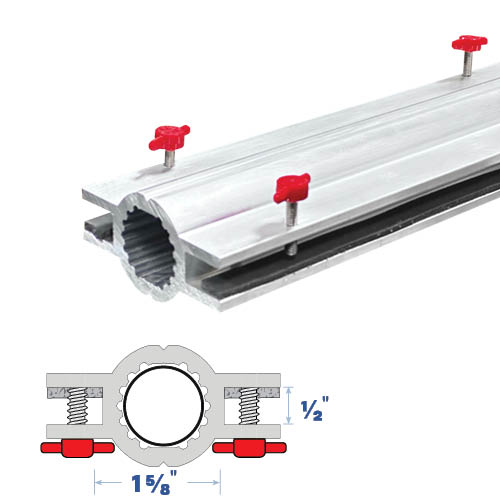

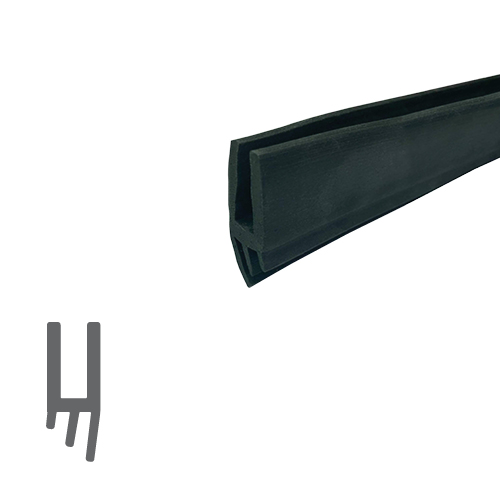

Legacy flood barrier panels are engineered for easy installation into pre-mounted aluminum brackets attached to frames or adjacent walls. When high water threatens, simply drop the barrier panel into the mounting channels and hand tighten the screw. Panels can be removed just as easily for storage when not in use. Closed cell sponge neoprene lines the bottom and sides of openings to ensure a watertight seal, as well as compensate for any gaps at door thresholds. These seals feature an innovative "three-finger" rubber profile for improved compression and better seals compared with conventional U-channel design.

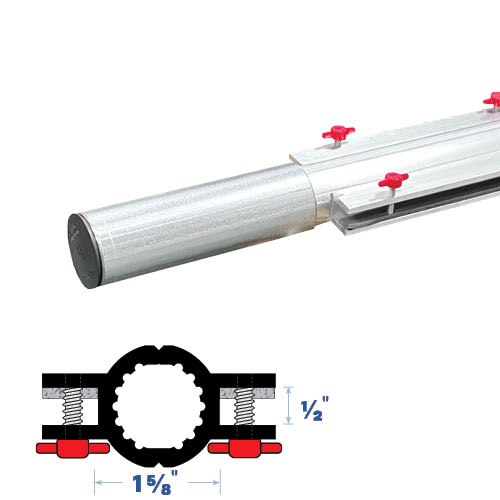

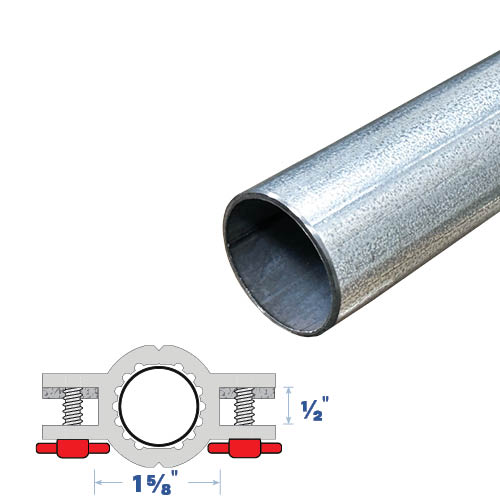

Constructed from marine-grade aluminum, the removable flood barrier panels can be built to any specified height and are also stackable using watertight bar clamps. Milled Easy-Lift handles are another recent design enhancement. Interlocking posts, including outer sleeves for ground support, are supplied for specified opening widths greater than 48 inches, which translates to virtually no practical limit on the width of protected openings or spans.

Suitable for both residential and commercial applications, Legacy flood barriers comply with standards of the Federal Emergency Management Agency (FEMA) and Federal Insurance Administration (FIA) for use on doors in flood-prone areas. They are also ideal for houses with adjacent wetlands or in high-rainfall areas.

Our mission is to provide a seamless experience for our customers. We accept orders via several different methods to facilitate your order. Because of the range of available options and the precision needed for efficient installations, Flood Barriers are typically specified in consultation with our Engineering Department.

Speak to a Customer Service Representative:

Local: +1 (718) 292-5333

Toll Free: +1 (888) 383-3330

Send an email to our Engineering Team:

orders@legacyllc.com

Sending photos of your project will expedite the process, along with taking measurements.

Panel: 5052 marine aluminum alloy

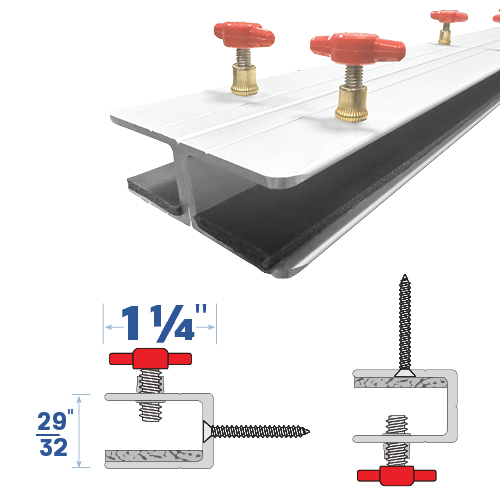

Frames: Channel 6062 alloy T5-T6, with 10-32 stainless steel Allen head tightening screws every 8" on center.

Seal: Sponge Neoprene within the channels and Solid Neoprene 3-Finger Rubber on the bottom of the panel.

Hardware: #10 x 1-1/4" FHPH with plastic expansion tube anchors.

Snap covers for safety provided for the top of the channels and for the mounting holes.

Installation: Can be installed on hollow metal, aluminum or wood frames; and on concrete, brick or metal surfaces.

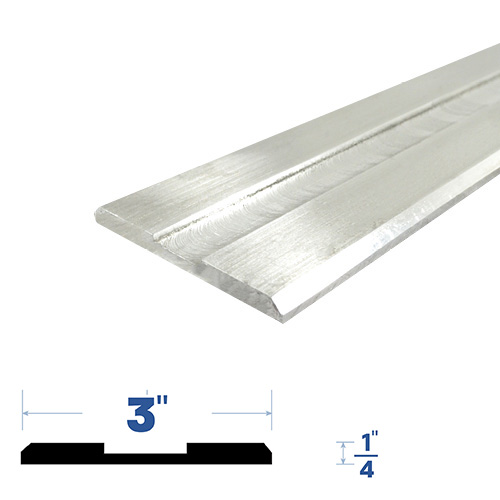

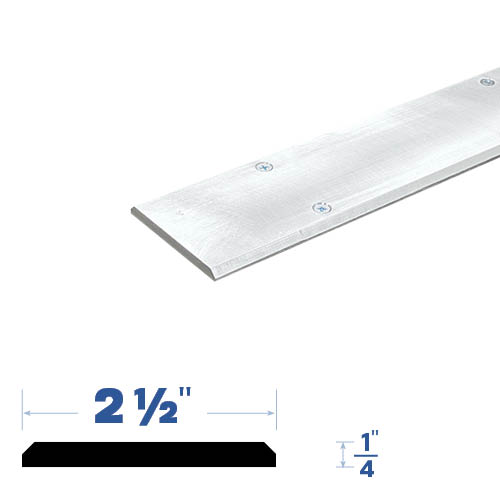

Floor Surface: Optional flat 1/4" x 2" bevels on 2 sides of the aluminum plate - #319 Threshold.

FAQ

Flood Barriers can be mounted to the inside or outside of frames. We also offer custom, free-standing barriers.

Installation Instructions:

1. Position the mounting channels in the desired location with larger holes facing exterior.

2. With channels vertically aligned, mark screw holes.

3. Drill pilot holes for screws using 9/64" drill bit.

4. Install channels with screws provided.

5. Caulk bottom outer edges of channels to the floor surface.

6. Ensure that the bottom is level and completely cleaned of all debris.

7. With label facing out, insert the bottom of plate into channels.

8. Apply force to the plate to compress rubber to the surface of the floor.

Two people may be needed to apply even pressure on both ends.

9. Tighten red screws. Make sure that there is no visible light coming through between the floor and rubber.

Our mission is to provide a seamless experience for our customers. We accept orders via several different methods to facilitate your order. Because of the range of available options and the precision needed for efficient installations, Flood Barriers are typically specified in consultation with our Engineering Department.

Speak to a Customer Service Representative:

Local: +1 (718) 292-5333

Toll Free: +1 (888) 383-3330

Send an email to our Engineering Team:

orders@legacyllc.com

Sending photos of your project will expedite the process, along with taking measurements.

Our barriers are built to protect ANY size opening, no matter how large. We have several options that can fit your project.

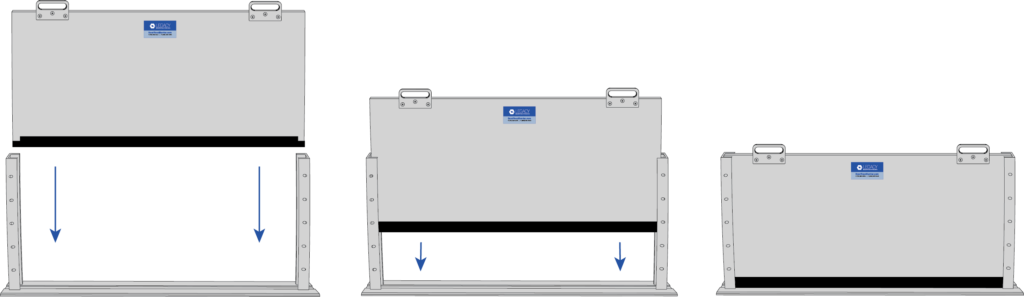

0"- 48" WIDE: Our single shield flood barriers are suited for up to 48" wide and 48" tall.

We recommend #5127

Greater than 48" WIDE: Our interlocking support components allow for any size opening to be protected.

We recommend #5129

Greater than 48" TALL: Our Stackable Flood Barrier allows for increased vertical protection by stacking two shields.

We recommend #5021

Inspect channels to ensure proper working condition.

Inserting Shield: With label facing out, insert the bottom of plate into channels. Lower the shield until there is a firm and even connection with the sill. Tighten the tension screws.

Removing Shield: Loosen the tension screws so the shield can be properly removed. Pull straight up on the plate to remove from channel.

Storing Shield: Store the shield indoors with no weight against the gasket